‘Anti Piping Compound’ is used in casting of molten metal. Just after pouring, it is important to maintain upper portion of the molten metal at nearly the same temperature as the molten metal in lower layers. This prevents formation of undesirable pipe on the upper layer of the molten metal by keeping its upper layer in molten state. This is achieved by preventing loss of heat through radiation. Thus ‘Anti Piping Compound’ is placed on upper layer of the molten metal. This ‘Anti Piping Compound’ ignites due to temperature of molten metal. This ignition compensates the heat loss and provides ‘Heat Gain’ through its Exothermic Reaction with molten metal. After burning, the residue expands and forms an insulation layer on the molten metal, preventing loss of heat due to radiation.

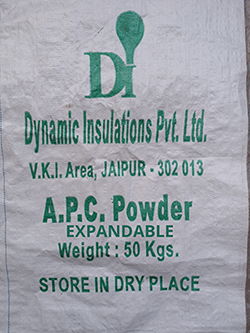

We strongly recommend foundryman to use this Expandable APC Powder for your riser size dia 75mm and above because of it’s characteristic of expansion gives better covering to riser which eliminates contact of riser metal from atmosphere temperature and slower downs riser cooling which give better result in feeding it almost reduces piping formation in riser.

Thus ‘Heat Gain’ is achieved and loss of heat is compensated at first and then insulation of molten metal is achieved using ‘Anti Piping Compound’ only.

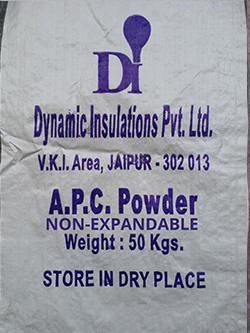

This Non-Expandable APC Powder is having very low carbon contents which almost nil, so it is recommended the foundryman to use this Non-Expandable APC Powder with the metal grades which are carbon sensitive it gives negligible carbon pickup in the riser metal from APC. It is to be used to width any steel and cast steel grades.

APC Powder eliminates contact of molten metal from atmosphere.

Exothermic Reaction compensates the heat loss and thus the temperatures on the upper and lower layers of molten metal are maintained.

Expands to entire surface of the molten metal thus achieving good spread-ability.

Provides insulation cover over the molten metal, thus preventing further ‘Heat Loss’.

Provides good quality of metal output and helps maintain quality standards.

Combination of good quality of sleeves with use of best quality of APC Powder results the best feeding of the riser.